Table of Contents

.jpeg)

Welding fumes are often the invisible threat in the workplace—dangerous yet underestimated. Exposure to these fumes is a daily reality for engineering, fabrication, or construction workers across New Zealand. While the sparks, heat, and bright arcs of welding are expected hazards, the microscopic airborne particles and toxic gases pose a longer-term risk to health. The good news is that respiratory protection technology has evolved. And with products like the Optrel Swiss Air PAPR Multi-Use Respiratory System and Clearmaxx Grinding Helmet Kit, welders now have an effective, comfortable, and practical way to protect themselves without compromising mobility or visibility.

This blog post explores the risks of welding fume exposure, the shortcomings of traditional protective measures, and why modern systems such as the Optrel Swiss Air PAPR are becoming essential gear in workshops nationwide.

Understanding the Dangers of Welding Fumes

Welding fumes are created when metals are heated above their boiling points, releasing vapours that cool and condense into fine, toxic particles. These fumes contain a mix of metallic oxides, silicates, and fluorides, many of which can seriously damage the respiratory system over time.

Short-term exposure to welding fumes can lead to symptoms such as dizziness, sore throat, coughing, and nausea. One common condition is " metal fume fever," a flu-like illness typically caused by inhaling zinc oxide fumes when welding galvanised steel. Although temporary, the condition can disrupt work and well-being.

The long-term health effects are far more serious. Studies have shown that prolonged exposure to welding fumes is linked to chronic bronchitis, asthma, lung function reduction, and even cancer. The International Agency for Research on Cancer (IARC) has classified welding fumes as a Group 1 carcinogen. Additionally, certain fumes, like those from manganese, can cause neurological symptoms resembling Parkinson's disease.

Welding also produces gases such as carbon monoxide, ozone, nitrogen oxides, and phosgene. In confined spaces, these gases can displace oxygen and lead to suffocation if adequate ventilation or protective equipment is not in place. The risks are clear and significant for engineers and welders, especially those working in enclosed areas or handling coated materials.

| Fume Type | Source | Health Effect |

| Aluminum | Aluminium is a component of some alloys, e.g., Inconel, copper, zinc, steel, magnesium, brass, and filler materials. | Respiratory irritant. |

| Beryllium | Stainless steel containing cadmium or plated materials, or zinc alloy. | Irritation of the respiratory system, sore and dry throat, chest pain and breathing difficulty. Chronic effects include kidney damage and emphysema. Suspected carcinogen. |

| Chromium | Most stainless-steel and high-alloy materials are used for welding rods and as plating materials. They convert to hexavalent chromium during welding. | Increased risk of lung cancer. Some individuals may develop skin irritation. Some forms are carcinogens (hexavalent chromium). |

| Copper | Alloys such as Monel, brass, and bronze. Also, some welding rods. | Acute effects include irritation of the eyes, nose and throat, nausea and “Metal Fume Fever.” |

| Fluorides | Standard electrode coating and flux material for both low- and high-alloy steels. | The acute effect is irritation of the eyes, nose, and throat. Long-term exposures may result in bone and joint problems. Chronic effects also include excess fluid in the lungs. |

| Iron Oxides | The primary contaminant in all iron or steel welding processes. | Siderosis is a benign form of lung disease caused by particles deposited in the lungs. Acute symptoms include irritation of the nose and lungs. Tends to clear up when exposure stops. |

| Lead | Solder, brass and bronze alloys, primer/coating on steels. | Chronic effects on the nervous, kidneys, digestive, and mental capacity. It can cause lead poisoning. |

| Manganese | Most welding processes are used for high-tensile steels. | “Metal Fume Fever.” Chronic effects may include central nervous system problems. |

| Molybdenum | Steel alloys, iron, stainless steel, and nickel alloys. | Acute effects are eye, nose and throat irritation, and shortness of breath. |

| Nickel | Stainless steel, Inconel, Monel, Hastelloy and other high-alloy materials, welding rods and plated steel. | The acute effect is irritation of the eyes, nose and throat. Increased cancer risk has been noted in occupations other than welding and is also associated with dermatitis and lung problems. |

| Vanadium | Some steel alloys, iron, stainless steel, and nickel alloys. | The acute effect is irritation of the eyes, skin and respiratory tract. Chronic effects include bronchitis, retinitis, fluid in the lungs and pneumonia. |

| Zinc | Galvanised and painted metal. | Metal Fume Fever. |

Traditional Protection and Its Limitations

Historically, the primary defence against welding fumes has involved a mix of ventilation, local exhaust systems, and tight-fitting respirators. Ventilation systems, where available, do reduce airborne contaminants. However, they are not always practical, particularly on outdoor job sites or in restricted spaces like tanks, crawlspaces, or marine vessels.

Tight-fitting respirators (including disposable and half-mask variants) are another layer of defence. Yet, they come with notable challenges:

They require a precise fit to be effective. Any facial hair can prevent a proper seal, rendering them ineffective

They often become uncomfortable after extended use.

Wearing them beneath a welding helmet can cause fogging of the lens and restrict breathing, prompting some users to remove them mid-task.

Many of these traditional systems also don't accommodate the need for clear communication, freedom of movement, and extended shifts in hot or humid environments. For the welder working long hours on the job, comfort and practicality are just as critical as protection. The question arises: how can welders protect their respiratory health without compromising performance and comfort?

The Modern Solution: Powered Air-Purifying Respirators (PAPRS)

Powered air-purifying respirators (PAPRS) are becoming increasingly popular in industries where workers are exposed to fumes and dust daily. A PAPR draws ambient air through high-efficiency filters and delivers purified air to the user's breathing zone, usually through a face shield or mask.

Unlike traditional respirators, PAPRS create a positive pressure environment inside the mask. This pressure helps prevent contaminants from entering the breathing zone, even if the mask doesn't form a tight seal against the face. This game-changer is for workers who find beards or tight-fitting masks uncomfortable.

PAPRS also reduces breathing resistance. The user doesn't have to manually pull air through a filter—the powered fan system makes breathing easier over long shifts. The constant airflow also helps to reduce heat and prevent visor fogging. These advantages have led to PAPRS being widely adopted in various industries, from heavy fabrication to agriculture, where air quality is a concern.

Introducing the Optrel Swiss Air PAPR & Clearmaxx Helmet Kit

One of the most advanced PAPR systems available today is the Optrel Swiss Air Multi-Use Respiratory System, combined with the Clearmaxx Grinding Helmet. Designed in Switzerland and engineered for industrial environments, this system represents a significant step forward in workplace safety.

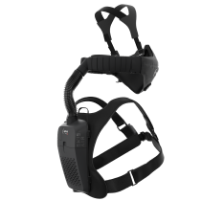

The Swiss Air PAPR unit includes a ventilated half-mask that supplies purified air directly to the mouth and nose. This mask is part of a complete system with a powerful blower, adjustable harness, and long-life battery.

The Clearmaxx Grinding Helmet, which pairs seamlessly with the PAPR unit, offers full-face protection with an unlimited field of view. Together, they provide welders and engineers with reliable respiratory and visual protection, whether working in welding bays, woodshops, food processing plants, or outdoors.

Let's explore the specific features and benefits of this system.

Key Features and Benefits

- TH3-Level Filtration: The Swiss Air unit is rated TH3—the highest protection class under European standard EN 12941. It filters out 99.8% of harmful airborne particles, including welding fumes, dust, vapours, and viruses.

- Positive Pressure Breathing: The blower creates a positive pressure inside the half-mask, supporting natural breathing and eliminating the fatigue associated with traditional respirators.

- Ergonomic and Lightweight: Weighing just over a kilogram, the blower and harness system is comfortable to wear all day. The weight is evenly distributed across the shoulders, reducing strain on the neck or back.

- 14-Hour Battery Life: With a full charge, the unit can operate continuously for up to 14 hours, allowing users to complete extended shifts without interruption.

- Beard-Friendly Design: The half-mask doesn't require a facial seal, making it effective for workers with beards—an essential consideration for many in the welding and engineering trades.

- Adjustable Airflow and Smart Controls: The system includes a central control panel that monitors battery and filter status, adjusts airflow, and automatically compensates for altitude and temperature changes.

- Versatile Compatibility: The Swiss Air system fits beneath any standard welding helmet. This means users can keep their preferred auto-darkening helmet while gaining respiratory protection.

- Clear Vision with Clearmaxx: The lightweight Clearmaxx Grinding Helmet provides broad, unobstructed vision with built-in air distribution to prevent fogging. It's suitable for grinding, cutting, and non-welding applications.

- Complete Package: The kit includes everything needed: a blower, control panel, half-mask, hose system, harness, charger, storage bag, and the Clearmaxx helmet.

This all-in-one approach makes the Optrel Swiss Air PAPR system suitable for various environments and tasks. Whether working in a confined space, handling galvanised steel, or performing long hours of fabrication, this system delivers protection without compromise.

Click HERE to see the Optrel Swiss Air Kit in action.

Real Results from Real Worksites

Engineers and welders across New Zealand have reported outstanding results from using the Swiss Air PAPR system. One professional working in the marine industry described how he used the system to grind out rust from a boat hull in a confined space. The compact and lightweight design allowed him to work comfortably without worrying about fume exposure or gear shifting out of place.

Another seasoned welder, who had struggled with fogged-up lenses and headaches from traditional masks, noted how the Optrel system allowed him to breathe freely and see clearly throughout the job. The ability to keep his beard and remain protected was a significant improvement over previous solutions that demanded a tight seal.

Many users say they wish they had upgraded their respiratory protection earlier in their careers. The message is clear—comfort leads to consistency. When safety gear is easy to use and comfortable, it gets worn. And when it gets worn, it protects.

Investing in Health and Compliance

PAPR systems represent a higher initial investment than disposable or half-face respirators. However, their value is undeniable when weighed against the cost of medical treatment, loss of productivity, or long-term illness.

In addition, regulations from WorkSafe New Zealand and international bodies increasingly require employers to assess and control fume exposure. Supplying effective PPE is no longer optional—it's a legal and ethical responsibility.

The Optrel Swiss Air PAPR system helps businesses meet those obligations while giving workers the tools to perform their tasks safely and efficiently. For workshop managers, investing in such a system is an investment in their workforce.

Welding fumes are more than an unpleasant by-product—they are a serious health hazard. Yet, with technological advancements, we can no longer choose between comfort and protection. The Optrel Swiss Air PAPR Multi-Use Respiratory System and Clearmaxx Grinding Helmet Kit provide a practical and user-friendly solution to one of the industry's oldest problems. They empower welders, engineers, and workshop professionals to protect their lungs, comply with regulations, and maintain productivity—all without sacrificing the comfort and mobility needed to do the job right. For those ready to take their safety seriously, this system offers more than just gear—it provides peace of mind.

Take the next step in protecting your future. Equip your team—or yourself—with a respiratory system built to perform and last. Your lungs will thank you!